|

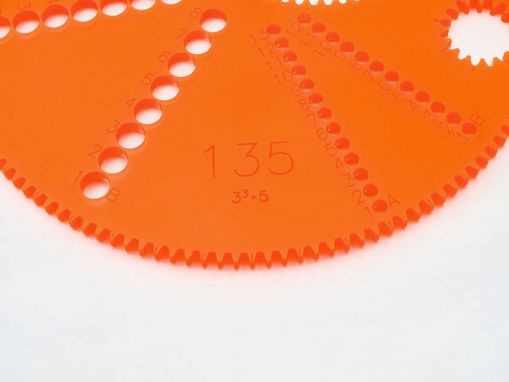

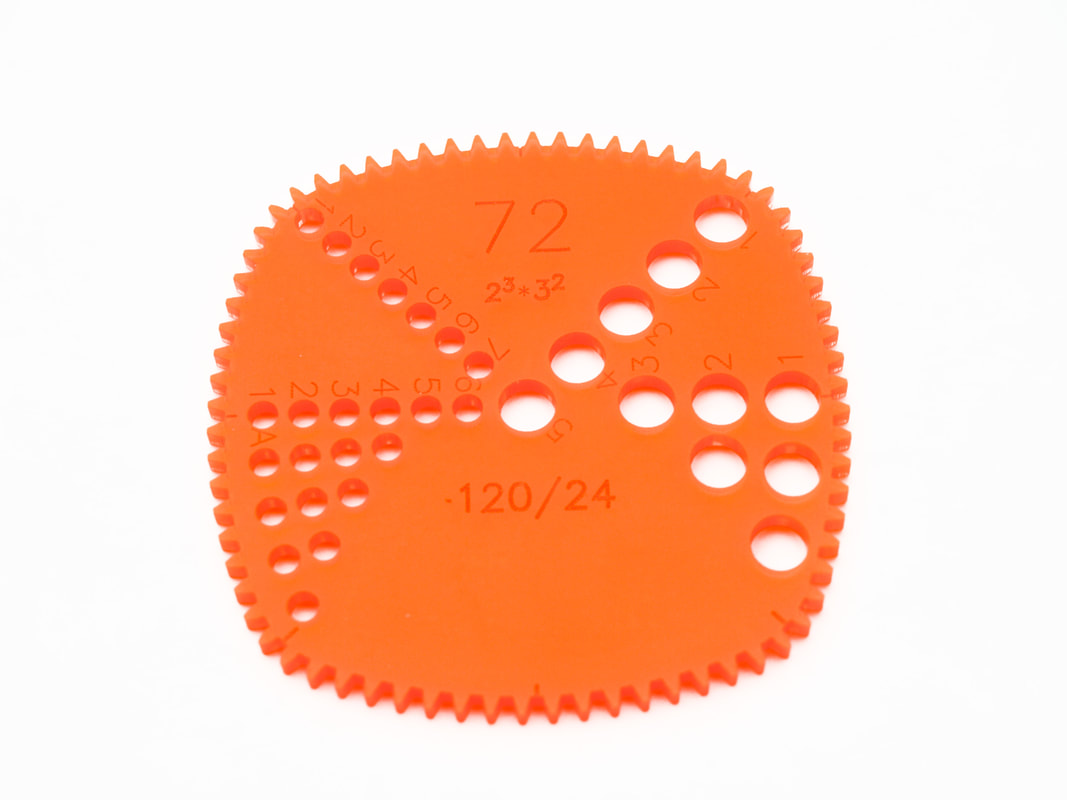

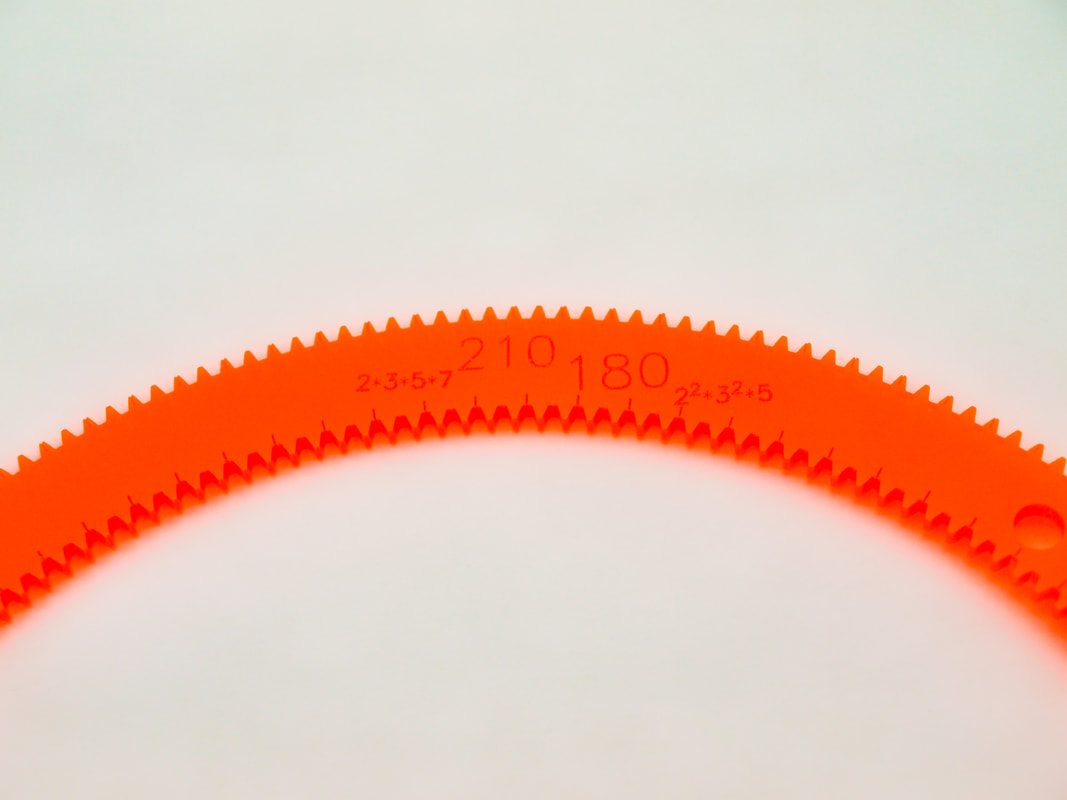

Today'll be a quick post about what all the different numbers on the gears mean. Most gears have two sets of numbers and non-circular gears have three sets. The biggest number is the tooth count of the gear. This is a measure of the circumference and is helpful to know when making design choices. Most gears also list the prime factors of the tooth count. Prime factors help predict how many lobes/petals/points a design will have. In the picture above the tooth count of the gear is 135 and the prime factors are 3^3*5 (3*3*3*5). Some small gears have the tooth count as their only number due to space constraints. Prime factors will still be listed where the number is engraved beside the ring. Some gears have a prime number of teeth and therefor don't have any factors to list. The numbers on the non-circular gears will be written as 'big number / small number' ( 120/24 for example). These numbers tell you about the different parts of the non-circular gears. These gears are constructed from arc-segments of different sized circular gears. A triangular gear that was 120/24 means that the flat 'sides' are made from part of a 120 tooth gear and the corners are made from part of an 24tooth gear. This is important to know because the resulting triangle gear will not work properly in a ring that is smaller than 120 teeth and the triangle ring will only work with gears that have fewer than 24 teeth (bigger ones will get stuck in the corners). There is also hoops which have an inside and outside tooth count. In the picture above the outside of the hoop has 210 teeth and the inside has 180 teeth. The prime factors of each are listed beside. On some hoops the tooth counts will be listed separated by a slash (210/180) due to limited space.

Additional note: Pen hole numbering Pen holes come in 4 sizes: small, medium, large, and extra small. Small pen holes are on every gear and have a diameter of 3 mm, medium pen holes are on most gears and have a diameter of 6 mm, large pen holes are on some gears and have a diameter of 9 mm, and extra small pen holes are rarely seen on very specific gears and have a diameter of 1 mm. Each line of pen holes is numbered starting at 1 at the edge of the gear and counting up until the line ends. Lines of the same size are marked with A, then B, and so on. Line A starts closer to the edge of the gear than line B. The distance between A1, B1, and A2 are the same; this allows placing more equally spaced pen holes on the gear than one line could hold. Non-circular gears also have 'side' and 'corner' pen holes to distinguish between.

2 Comments

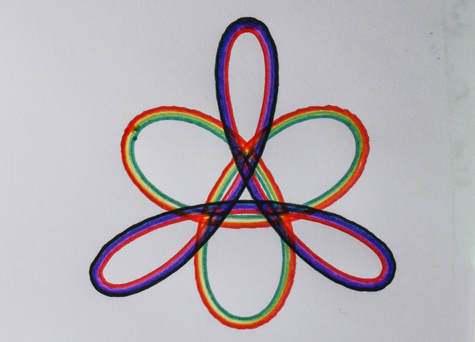

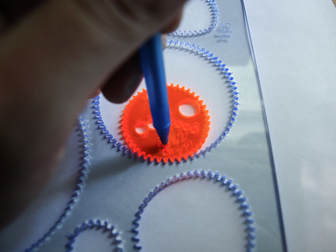

Using the little cylinders ('doughnuts') that go into the medium and large holes can yield a wide variety of results. This post is a starting point for developing further techniques. Gear Sets come with a range of sizes of the doughnut pieces with each one provided with some duplicates; recognizing how easy they are to lose. The multitude of them can make it hard to determine how many sizes there are and what size any one piece is. When I start using the doughnut pieces I'll line them up by size, removing ones that I can recognize to be of the same size. To calibrate the doughnuts take a simple ring-gear combination (72:36 for example) and start with the doughnut with the biggest hole and make the design. Switch colours; ideally to a lighter one, black to red is very good for this. Using the lighter colour and the next doughnut piece in the line repeat the design. If it is the same size then the red line will not show up as it is directly on top of the black line. If it is a very little bit different the red line will show up very close to the black line. Depending on the pen type there may be no white space between the two lines. If the size difference between the pieces is larger there will be a blank pinstripe gap between the two lines. This process can be repeated to calibrate the sizes between all the doughnut pieces in the line; sorting them by size and removing any duplicates as well as informing the relative step sizes between them. Note: Using different brands of pens will yield different line positing too. For this calibration step use two pens of the same brand, or stick to just one pen. In this photo I have finished the calibration step and selected 4 different sized doughnut pieces. I have them lined up so that I don't get confused. I've selected colours to go with each step and you can see that black and red are aligned with a 5th blank step that corresponds to using the medium pen hole without a doughnut piece. The picture below was made using 72:48 1B (+4Hoops), (12 CCW) 2B (+4Hoops) where 1B used Black, Blue, Dark Blue, Purple, and Red and 2B used Red, Orange, Yellow, Light Green, Dark Green. Notice that the pen lines and colours are each distinct but have not white space between them. Because these pen colours overlap just a bit the stronger colours dominate and the central lines look narrower. Depending on pen line weight it is possible to use this effect to make a narrow pinstripe of colour down the middle of a black line by sandwiching a line (I like red or gold for this effect) between two heavy black lines. More space can be made for each individual line and colour by choosing doughnut pieces that provide more space, like in this next example. These are the core techniques of how to determine the spacing provided by the doughnut pieces and some different ways to begin using them. By experimenting with spacing, colour, and line weight you can create incredibly diverse and powerful variations on a design.

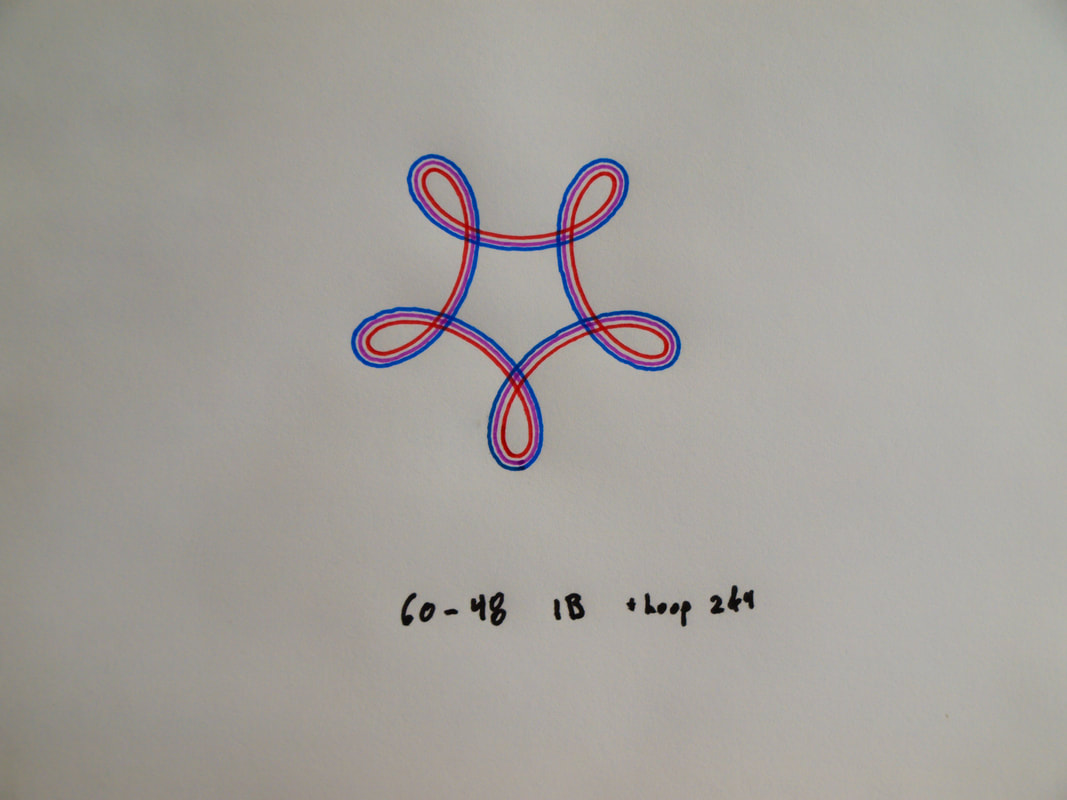

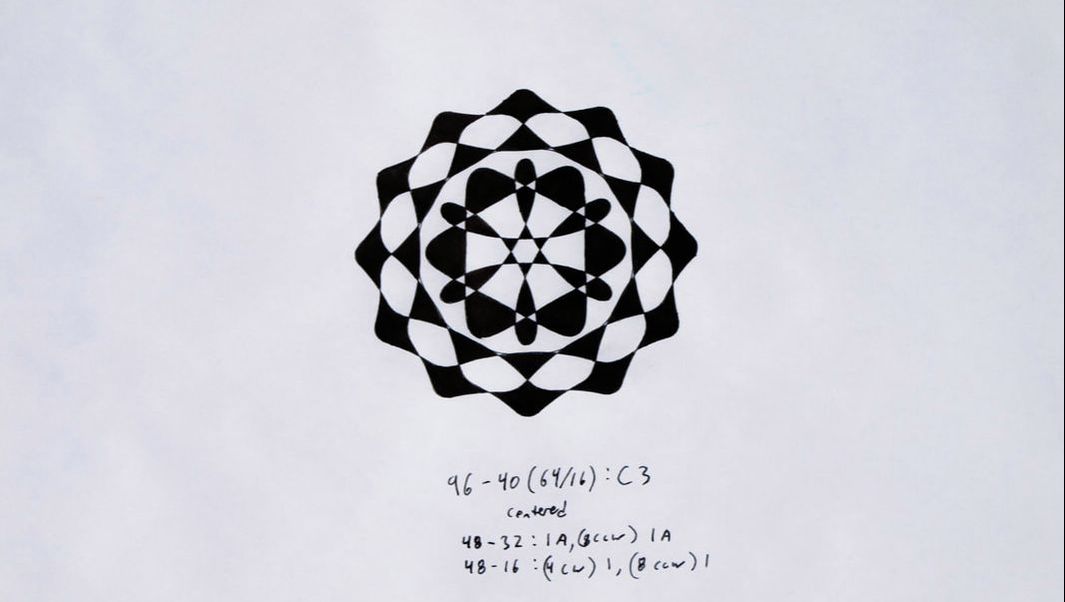

The tightly packed parallel lines made by the doughnut pieces also appear different at different distances. Quite some time ago I made a design that was composed of a tightly packed set of these lines that played to tartan inspired colours and and spacing. Much to my surprise, at a distance it looked more like a beige design but it caught the eye in a hard to describe sort of way. When approaching the piece I would cross a some critical distance and all the individual colours in ti would snap into focus and it would suddenly appear colourful. I'll try and find this piece and share it in a future post, but I have no idea how to capture this feeling of it photographically. Thank-you for reading. Have fun! Aaron Bleackley I've been making my own shorthand notation for how I made designs for several years now and slowly refining it. This post can be a starting point in trying to codify any of it. Hopefully this will be the start of a useful shorthand. Today, I'll lead with the picture and we can work from there. I made a complex piece using several designs layered on each other. Lets start with a copy of the notation below the design and then I'll break down what each part means and why it is structured the way it is. Hopefully this description will enable you to make use of the notation for yourself if you are so inclined. 96-40(64/16) : C3 centered 48-32: 1A, (8 CCW) 1A 48-16: (4 CW) 1, (8 CCW) 1 There are four lines; each giving information about a different stage of the design.

These steps form the lines of the design. I then coloured it in a checkerboard pattern starting by colouring all the outer cells and alternating on my way into the center of the design. This picture is a visual reference for the 6 O'clock starting point described in step 3. In this case it would be for the design 72-42: 2A.

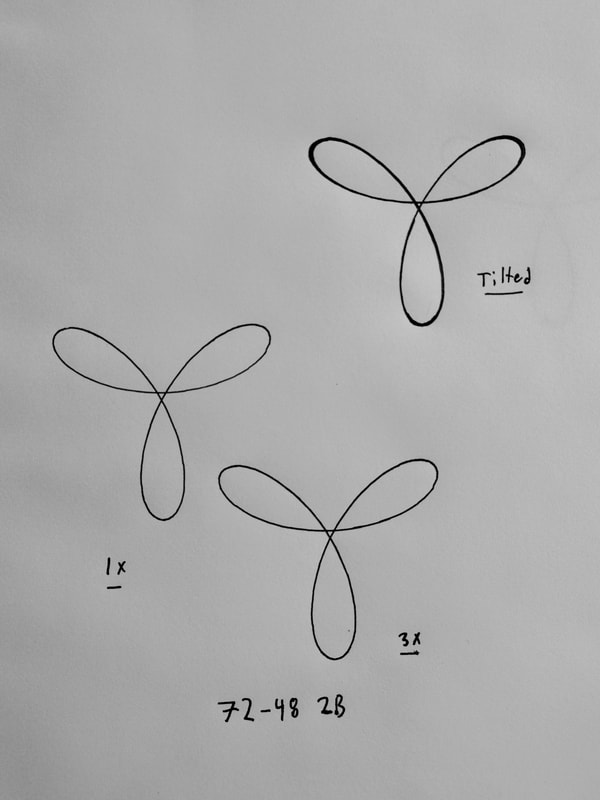

This is a starting point for developing a broader notation involving more details and types of designs. This should prove to be a robust starting point for gear-in-ring style designs. Previously I've posted pictures and videos to various parts of the internet highlighting interesting, pretty, and often complex designs that I've made with Wild Gears. I'd like to make a slightly different space for posts and pictures that talk about different techniques of using Wild Gears. This will start building a knowledge base for people to bring to their own creativity and exploration. I'm going to start simple and short with a few pictures and hopefully not too many words. Today's topic is pen angle. When starting to use Wild Gears the aim is usually to make clear crisp lines and uniform designs. This is best achieved by holding the pen vertically; rather than angled like is more common when writing. Applying consistent pressure and speed is also good (some pens need that much more than others). The first trick to get a better looking line is to go over the design two or three times. This gets a solid ink line that looks bolder and crisper. It also helps hide the point where the design started and stopped. Now that you've got the hang of making solid consistent lines thought complex designs lets look at how to add subtle body and emphasis to the lines. A lot can be done by tilting the pen while going over the design an additional time. The key is to be aware of how and when the pen is tilted. For example tilting the pen consistently to the left will give a different line weight pattern than tilting the pen towards the center of the ring at all times. This picture shows a very simple design that has been done three ways.

The 1x design looks similar to the 3x design but the 3x design is more bold and stands out better but both have uniform line thickness. The top right design 'Tilted' shows off narrow lines near the center and thicker swooping lines near the edges. The top right lobe is the best example.

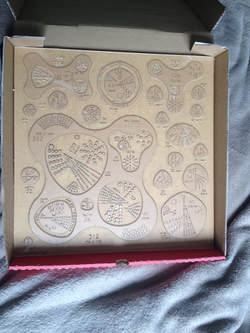

Clearly, these photos also need better lighting to do them justice but for now it is good to be getting started. If you have questions, comments, or want more details about pen angle, I'd love to hear from you. Thank-you for reading, ~Aaron Doing some spring cleaning and organization led to a discovery of two Strange Shapes Gear Sets V2. If you want a Strange Shapes Gear Set for half the regular price act now! (supplies are limited) Note: These are version 2 Strange Shapes Gear Sets (V3 is current). They have all the same parts but lack the hatch marks around the edges of the gears as well as the numbered pen holes and the prime factors listed on each piece.  The gear set in the picture has had some of the brown paper layer removed from one side to make the pieces stand out better.

I often get asked about how to store and organize wild gears; especially the large sets. There are many creative and wonderful ways that people have shared with me that they have come up with. Perhaps I'll collect some of them for another post in the future. But right now I want to tell you about the simplest storage solution that I have found. Pizza boxes. Wait, clean pizza boxes. The pizzeria down the street will sell me pizza boxes for $0.50 each. I got an extra large pizza box and it holds large gear sets very well. Large Gear Sets are 15 inches, and small gear sets are 7 inches. You can probably even get blank pizza boxes somewhere if you look around. Cardboard is light, durable, and easy to decorate. I like this solution, and will probably employ it for several of my gear sets because it lets me stack, label, and organize things and I really like the low profile boxes for not taking up more space than is needed. Bonus cat (Echo) for scale. Echo was being very sweet as I shared her spot in the sun for this photo.

|

AuthorAaron Bleackley, designer of Wild Gears Archives

July 2024

Categories |

Wild Gears

BLOG and

BLOG and

Newsletter

Proudly powered by Weebly

RSS Feed

RSS Feed